Gotion is in the process of exploring a battery plant in the US, and the site is close to being decided, a company executive said.

Gotion High-tech, the Volkswagen-backed Chinese power battery giant, reported strong first-quarter results and revealed more about the company's plans to build a battery plant in the US.

Gotion reported first-quarter revenue of RMB 7.18 billion yuan ($1.04 billion), up 83.16 percent from a year earlier, despite a 16.8 percent decrease from the fourth quarter, according to an exchange announcement Friday from the Shenzhen-listed company.

The year-on-year increase in revenue was mainly due to growth in sales, Gotion said in the announcement.

The company reported a net profit of RMB 75.61 million in the first quarter, up 134.81 percent from a year earlier, but down 53.04 percent from the fourth quarter last year.

China's new energy vehicle (NEV) sales saw strong growth in the fourth quarter of last year, as consumers seized the last chance to get state subsidies for NEV purchases. For the first quarter, while it is usually a slow time for auto consumption, a rare price war this year delivered an additional blow.

China's first quarter NEV sales were 1.32 million units, up 23.72 percent year-on-year, but down 26.62 percent from the fourth quarter of last year, according to the China Passenger Car Association (CPCA).

Gotion, China's fourth-largest power battery manufacturer, saw its performance reflect these seasonal trends.

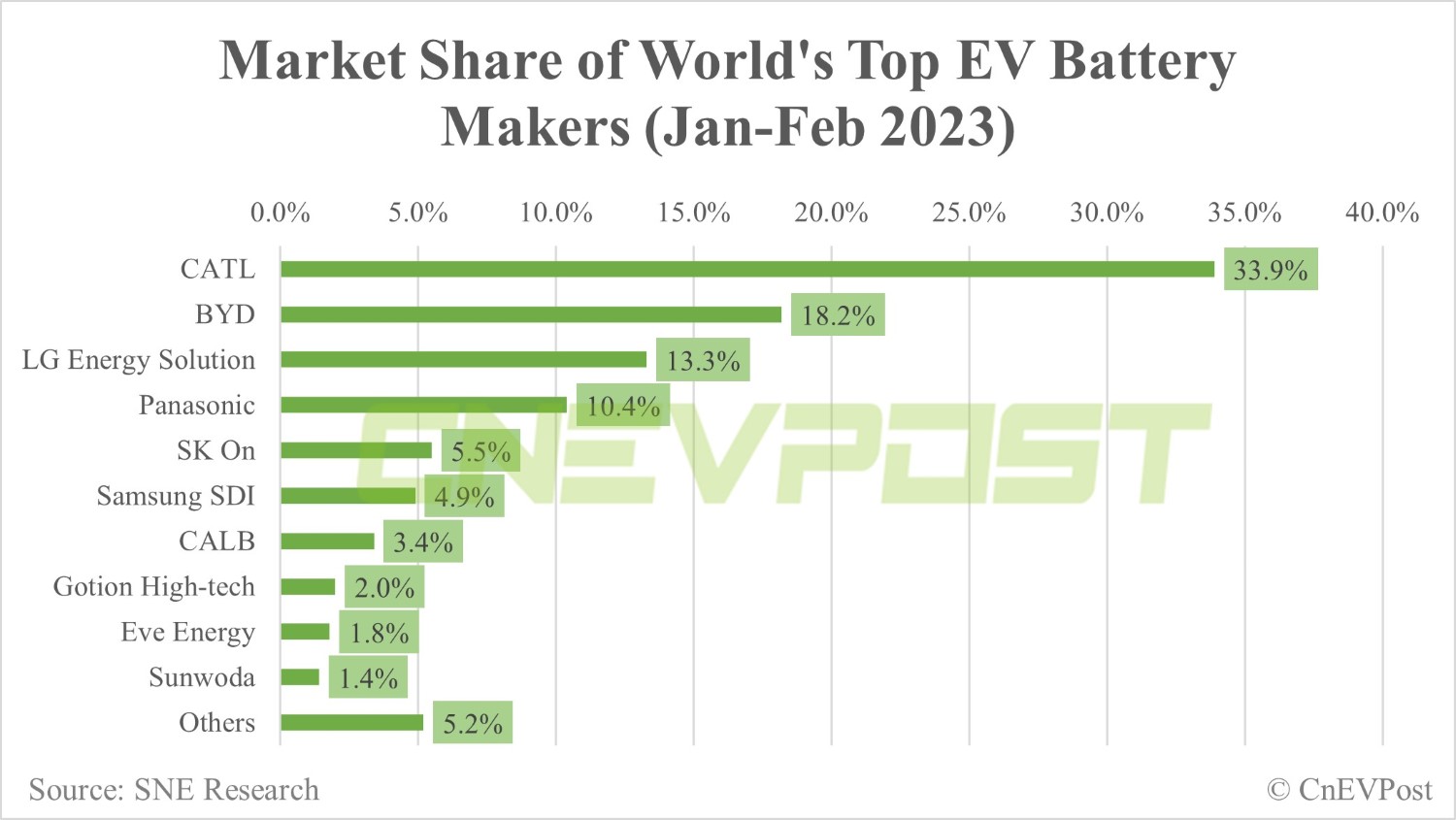

In March, Gotion installed 1.25 GWh of power batteries in China, ranking fourth with a 4.51 percent share, according to the China Automotive Battery Innovation Alliance (CABIA).

Gotion aims to exceed 300 GWh of capacity by 2025, according to its previously announced plans.

In addition to its quarterly earnings report, Gotion announced its annual report, which showed it had revenue of RMB 23.05 billion in 2022, up 122.59 percent year-on-year.

Gotion's revenue in overseas markets in 2022 was RMB 2.98 billion, up 464.76 percent year-on-year.

The company's profit in 2022 was RMB 199 million, up 408.87 percent year-on-year.

US battery factory nears

Gotion is conducting an in-depth exploration of building a battery factory in the US, and the site is now close to being determined, the company's vice president of international operations Ray Chen said Friday while speaking with media, including CnEVPost, at its Hefei headquarters.

The company is well on its way to building a plant in the US as an early move to capture the explosive growth opportunities in the US and Europe in 2025-2027, Chen said.

Influenced by the Inflation Reduction Act, Gotion's US plant is necessary, he added.

"The US and Europe are at the point where rapid growth is about to begin in this industry, and we certainly can't afford to give that business away," Chen said.

Gotion is currently selling batteries to US customers through exports, with sales expected to be $500 million this year, according to the company.

Notably, on October 5 last year, Michigan Governor Gretchen Whitmer said in a statement that Gotion chose to build its $2.36 billion battery component manufacturing facility in Big Rapids.

The Michigan Strategic Fund (MSF) Board approved the investment by Gotion, which will launch a multi-phase project in Big Rapids to build a battery component manufacturing facility there to serve its entire North American and global customer base, according to the statement.

Once completed, Gotion's plant is expected to produce 150,000 tons of cathode material per year, with two 550,000-square-foot production plants planned as well as other supporting facilities, the statement said.

Gotion chairman Li Zhen said at the media event Friday that the battery materials plant is sited in Michigan partly because of the relatively inexpensive supply of hydroelectric power in the area.

Gotion has been in contact with the local government for about two years, and final approval for the plant is pending, Li added.

($1 = RMB 6.9150)

Gotion to build $2.36 billion battery materials plant in Michigan

The post Gotion posts 135% year-on-year profit growth in Q1, site for US battery plant nears finalization appeared first on CnEVPost.

For more articles, please visit CnEVPost.